Stanley Laminated Blades – Swedish Iron

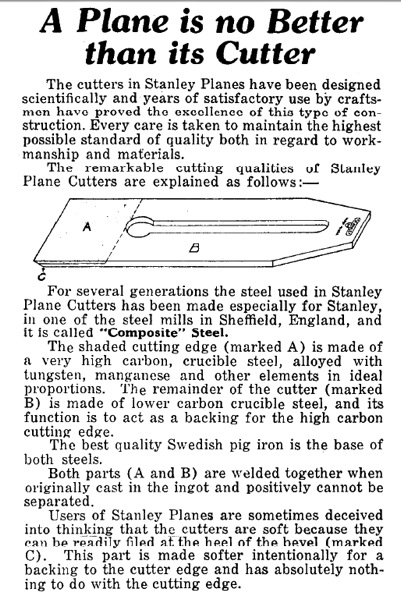

Stanley used laminated plane blades for several decades in the 20th century. They called these “Composite Steel” blades and they were made in Sheffield, England using pig iron from Sweden.

It’s not clear yet whether these blade were unfinished blanks or finished blades when they were shipped from England to the U.S.

Most of the research in this area has concentrated on Stanley Bailey metal bench planes My own research indicates that Stanley started using composite blades around 1909 with their TmT trademark blades (1909-1912). From all accounts, they stopped being made around 1941 with their TmBB Trademark blades (1935-present). The 1941 end date coincides with Great Britain’s involvement in the war and wartime industrial production.

Stanley likely had a good stock of composite TmBB, because they appear on planes well into the 1940’s, especially on the less common planes like the #4-1/2’s and #5-1/2’s and so on. That makes sense since it probably took years to use up the old composite blade stock for the less common Bailey plane sizes.

Not all Stanley Baily plane blades made between 1909 and 1941 were laminated. Some were not. This has created some confusion about these blades.

Here is a close-up example of a Stanley Bailey plane blade from around 1930. The two layers of different steel are clearly visible.

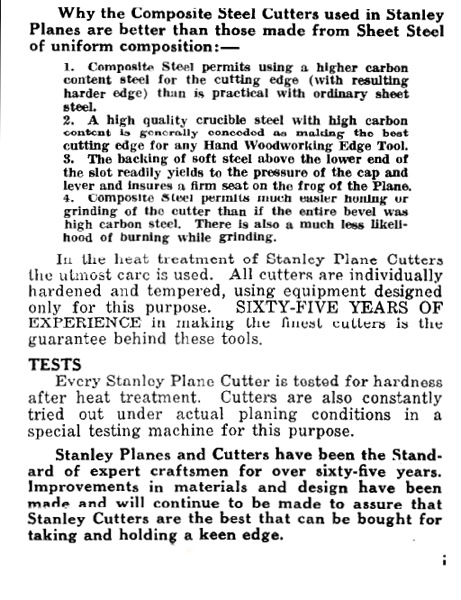

The Stanley brochure below was printed in 1921 and provides interesting details about the Stanley composite blades. I have have seen another one from 1933 and it is essentially the same except for a few cosmetic changes.

Because of the nature of these composite blades, it is not advisable to flip the blade back-to-front and grind a bevel the other way. While this does not seem to be a common practice, I have heard of some people doing this when the front of the blade is flatter or less pitted than the back. If this is done, the soft steel on the back of the blade will not be able to hold a good edge and will fold easily.

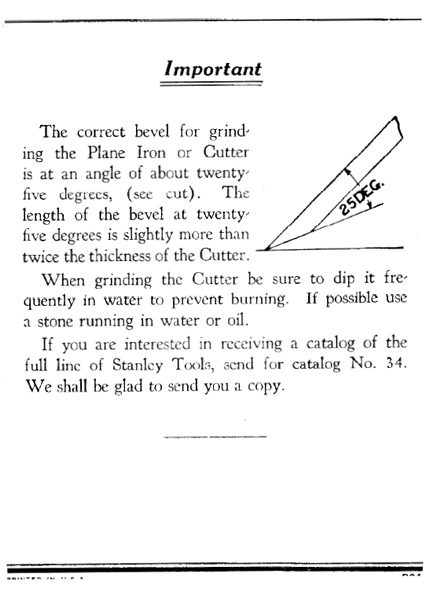

The back page of the brochure provides information on how to sharpen the blades.

You can purchase laminated stanley type blades at the following website. It is a Japanese tool specialty site, and not surprisingly sells an upgraded laminated blade with the wry comment that Western single layer steel blades are difficult and time consuming to sharpen to a good edge:

www2.odn.ne.jp/mandaraya/seiyoukannnaba.html

I have the same leaflet purchased with a post War Sheffield made Stanley No. 5 1/2 Plane.

There were also laminated irons with HSS Steel made and sold only in Australia. They were developed by Titan Tools, which was eventually bought out by Stanley and were specifically for the Australian market as our local hardwoods are harder and higher in silicates than most American and European timbers. As far as I am aware these irons were made up until the 1980s. They are also slightly thicker than standard irons. I’ve put one in my No.4 smoothing plane and I can get 0.002″ shavings in tropical hardwoods with it.